GENERAL FEATURES

- The clear oxygen (02) and carbon dioxide (CO2) gases, which are dissolved in the steam boiler water, can cause to damage the metal surfaces of the steam fittings.

- (Form 1 and Form 2), these corrosive gases; to remove the nutrients from the body of water; CO2 is separated by evaporation of CO2 at 60° C and O2 above 100° C on site by separating the feed water into small fractions and by heating with steam.

- (Form 3, Form 4) In the classical thermic degasifier system, process of separation of the feed water into small fractions is made by the sprinkler system.

- The drawbacks of this system are;

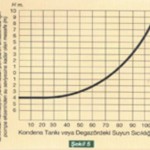

In order to avoid evaporation and cavitation in the intake of the feed water pump, the water level height in the degasifier must be at least 6 m. above from suction nozzle of pump. - (Form 5) it is necessary that the height of the boiler room must be 10 m to achieve this. This means that the cost of construction of the boiler room increases unnecessarily. In addition, the cost of construction and steel construction to be installed for the system to be brought up is also emerging.

Türkçe

Türkçe English

English